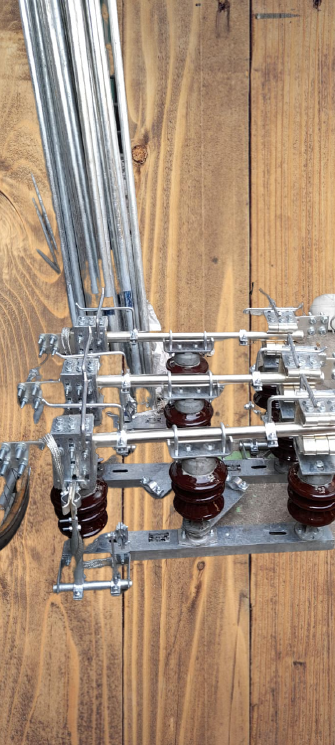

11 Kv Rotating Isolator

Price 16000-18000 INR/ Set

11 Kv Rotating Isolator Specification

- Product Type

- Isolator

- Material

- Porcelain, Brass, Iron, Bolts & nuts etc.

- Welding Standard

- As per Standard

- Capacity

- 400 Amps

- Application

- Electrical Distribution Lines

- Galvanization Standard

- IS SPECIFICATION

- Out Coating

- Galvanized Channel

- Standard

- IS Specifications

- Shape

- Rectangular

- Surface Treatment

- Hot Dip Galvanized

- Height

- As per Drawing Millimeter (mm)

- Voltage

- 11 KV

- Design

- As per Drawing

- Thickness

- As per Drawing Millimeter (mm)

- Color

- Brown

- Warranty

- 12 Months

11 Kv Rotating Isolator Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Howrah

- Payment Terms

- Cash Advance (CA), Telegraphic Transfer (T/T)

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 30-45 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Isolator are packed in Wooden Box, Operating Accessories in Bags & Loose Bundles.

- Main Domestic Market

- All India

- Certifications

- Routine Test Reports

About 11 Kv Rotating Isolator

11 Kv Rotating Isolator

TECHNICAL SPECIFICATION

|

Usage/Application |

OVERHEAD LINE |

|

Brand |

ELECTEROMECH INSULATORS & SWITCHGEARS |

|

Voltage (Kv) |

11 KV |

|

Tensile Strength (Kn) |

|

|

Power (Kw) |

N.A. |

|

Capacity (Kv) |

11 KV |

|

Weight (kg) |

60 |

|

Material |

PORCELAIN |

|

Color |

DARK BROWN |

Precision Engineering for Enhanced Safety

Our 11 KV Rotating Isolator is meticulously designed as per provided drawings to ensure a perfect fit in modern electrical distribution setups. With components made from high-quality porcelain, brass, iron, and secure bolts and nuts, it provides reliable isolation and maintenance for high-voltage applications, keeping personnel and equipment safe.

Superior Durability through Galvanized Protection

Featuring a hot dip galvanized channel and out coating, this isolator excels in withstanding harsh environmental conditions. The galvanization process, adhering to IS specifications, helps prevent corrosion and enhances the life expectancy of the device, making it a trusted choice for electrical infrastructure in demanding locations.

FAQs of 11 Kv Rotating Isolator:

Q: How is the 11 KV Rotating Isolator installed in electrical distribution lines?

A: The 11 KV Rotating Isolator is installed according to the specified engineering drawings, ensuring precise thickness and height for each site. It should be mounted using the supplied bolts and nuts, and fixed securely onto the distribution structure as per the standard procedures provided by electrical safety guidelines.Q: What materials are used in the construction of this isolator, and why?

A: This isolator is constructed from porcelain, brass, and iron, with robust bolts and nuts. Porcelain provides excellent electrical insulation, while brass and iron guarantee both mechanical strength and conductivity. Hot dip galvanized surfaces extend longevity by preventing rust and corrosion.Q: When should this isolator be used, and what is its current handling capacity?

A: This rotating isolator is ideal for use during routine maintenance and repairs on 11 KV electrical distribution lines to safely isolate sections of a circuit. It is rated for a capacity of 400 Amps, ensuring efficient performance even under high load conditions.Q: Where does the galvanization process add value to the product?

A: The hot dip galvanization process covers the channel and out coating, in full compliance with IS standards. This treatment forms a protective layer against environmental factors such as moisture, chemicals, and pollutants, which is especially valuable in outdoor or harsh operating environments.Q: What is the typical process for maintaining this isolator?

A: Regular visual inspections should be conducted to ensure there is no visible damage, corrosion, or wear on porcelain and metal parts. During scheduled maintenance, verify the tightness of bolts and integrity of the galvanization. Always follow safety guidelines while performing maintenance on energized lines.Q: How does the design as per drawing benefit installation and operation?

A: Manufacturing as per customizable drawings ensures the isolator precisely matches project requirements for dimensions and configuration. This reduces installation errors, speeds up setup, and improves operational compatibility with existing systems.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Air Break Switches Category

11 KV 2 Post Air Break Switch

Price 6400.00 INR / Set

Minimum Order Quantity : 1 Set

Design : As per Drawing

Color : Silver with Brown glazed Porcelain Insulators

Shape : Rectangular

11kv Air Break Switch With D O Fuse

Price Range 14000.00 - 18000.00 INR / Set

Minimum Order Quantity : 1 Set

Design : As per Drawing

Color : Silver with Brown glazed Porcelain Insulators

Shape : Rectangular

33 KV 400 Amps Air Break Switch

Price 17000.00 - 26000.00 INR / Set

Minimum Order Quantity : 1 Set

Design : As per Drawing

Color : Silver with Brown glazed Porcelain Insulators

Shape : Rectangular

22 KV Gang Operated Air Break Switch

Price 17000.00 INR / Set

Minimum Order Quantity : 1 Set

Design : As per Drawing

Color : Silver

Shape : N.A.

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese