Spiral Earthing Coil

Price 130.00 - 150.00 INR/ Piece

Spiral Earthing Coil Specification

- Product Type

- Earth Wire Hardware Fittings

- Material

- G.I. Wire

- Welding Standard

- N.A.

- Capacity

- N.A.

- Application

- Earthing Purpose

- Galvanization Standard

- IS SPECIFICATION

- Out Coating

- Hot Dip Galvanized

- Standard

- REC Specifications

- Shape

- Round

- Surface Treatment

- Polished

- Height

- As per drawing Millimeter (mm)

- Voltage

- 11 KV

- Design

- As per Drawing

- Thickness

- 4 Millimeter (mm)

- Color

- Silver

- Warranty

- 12 Months

Spiral Earthing Coil Trade Information

- Minimum Order Quantity

- 50 Pieces

- FOB Port

- Howrah

- Payment Terms

- Cash Advance (CA), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30-45 Days

- Packaging Details

- Gunny Bags

- Main Domestic Market

- All India

- Certifications

- Routine Test Report available

About Spiral Earthing Coil

We provide our customers with premium quality Earthing Coil.The offered products are widely acknowledged by the customers because of their features like high tensile strength, resistance to corrosion and longer functioning life. Our highly experienced professionals develop these earthing coils in accordance with the defined quality standards and using advanced technology. Further, these are well checked by our quality analysts to provide our customers with a detect free range of earthing coils.Tailored Design and Superior Build Quality

Each Spiral Earthing Coil is custom-made according to precise client drawings, ensuring compatibility with a variety of installations. The 4 mm thick, round G.I. Wire construction provides durability and optimum conductivity for earthing solutions. Stringent adherence to REC and IS specifications assures lasting performance and safety compliance in diverse environments.

Advanced Galvanization for Longevity

The coils hot dip galvanized finishing offers remarkable resistance against corrosion, which is vital for components in outdoor and industrial applications. A polished surface further safeguards the product, enhancing electrical conductivity and reliability under challenging atmospheric conditions.

FAQs of Spiral Earthing Coil:

Q: How is the Spiral Earthing Coil installed for optimal earthing?

A: Installation should follow the approved drawing, with the coil buried at an appropriate depth in a vertical or inclined position to maximize soil contact. Connections to the main earthing system should be rigid and secure, using suitable clamps or connectors compatible with G.I. Wire.Q: What are the key benefits of using a Spiral Earthing Coil for grounding systems?

A: The coil provides low-resistance grounding, which protects equipment and personnel from electrical faults. Its spiral design and robust galvanization enhance soil contact, corrosion resistance, and reliability, ensuring a longer service life and effective dissipation of fault currents.Q: When should a spiral earthing coil be preferred over other earthing methods?

A: Spiral earthing coils are ideal when space is limited or where rapid, efficient dissipation of fault current is essential, such as substations, power distribution sites, and industrial facilities operating at up to 11 KV.Q: Where can these Spiral Earthing Coils be sourced in India?

A: They are available through reputable manufacturers, suppliers, retailers, and traders across India. Clients should seek out vendors compliant with REC and IS standards to ensure product quality and warranty coverage.Q: What is the process behind the hot dip galvanization and why is it important?

A: Hot dip galvanization involves immersing the G.I. wire coil in molten zinc, creating a protective, corrosion-resistant layer. This process significantly extends the coils lifespan, particularly in harsh outdoor or damp soil environments.Q: How does adherence to REC and IS specifications benefit the end user?

A: Compliance with REC and IS specifications guarantees product reliability, interchangeability, and safety. It assures end users of high-quality materials and manufacturing practices, reducing maintenance needs and risks.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earth Wire Hardware Fittings Category

Earth Wire Tension Clamp Bolted Type

Price 350.00 - 370.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Hot Dip Galvanized

Design : As per Drawing

Shape : Gun type

Material : Malleable Cast Iron with Forged Anchor Shackle and Bolt, nut, washer

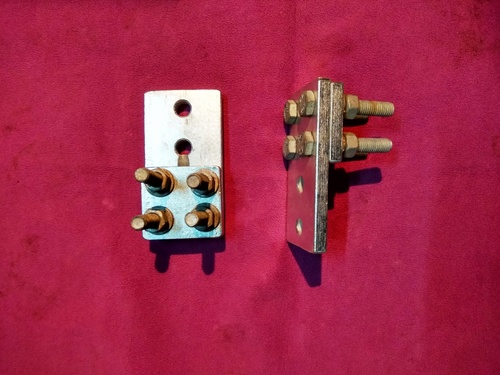

Earth Wire P.g. Clamp

Price 120.00 - 150.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Polished

Design : As per Drawing

Shape : Rectangular

Material : M.S. Plate

Pad Clamps For Earth Wire

Price 340.00 - 360.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Polished

Design : As per Drawing

Shape : Rectangular

Material : M.S. Plate

Repair Sleeves For Earth Wire

Price 90.00 - 100.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Surface Treatment : Polished

Design : As per Drawing

Shape : Round

Material : Aluminium and Mild Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese