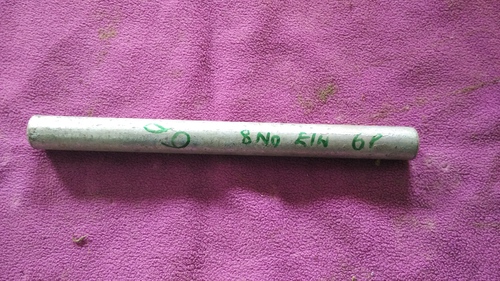

Earth Wire Tension Clamp Compression Type

Price 400.00 - 450.00 INR/ Piece

Earth Wire Tension Clamp Compression Type Specification

- Product Type

- Electrical Overhead Line

- Material

- Mild Steel

- Welding Standard

- As per Standard

- Application

- Industrial

- Galvanization Standard

- IS SPECIFICATION

- Out Coating

- Hot Dip Galvanized

- Standard

- IS Specifications

- Shape

- Gun type

- Surface Treatment

- Hot Dip Galvanized

- Height

- As per drawing Millimeter (mm)

- Design

- As per Drawing

- Thickness

- As per Drawing Millimeter (mm)

- Color

- Silver

- Warranty

- 12 Months

Earth Wire Tension Clamp Compression Type Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Howrah

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Cash Advance (CA)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Gunny Bags.

- Main Domestic Market

- All India

- Certifications

- Routine Test Reports available

About Earth Wire Tension Clamp Compression Type

Earth Wire Tension Clamp Compression Type

Being a reputed Manufacturer and Supplier, we are providing a wide range of Tension Clamp for Earth wire Compression type. The provided accessories are used in electrical and construction sectors. Our offered accessories are manufactured with utmost precision with the latest technology at our Works. Our entire product range ensures easy installation and is abrasion resistant. They are delivered in standard lengths and thickness and can be customized as per the requirement.

Features:

- Excellent flexibility

- High durability

- Accurate dimensions

- Resistant to corrosion

Precision Engineering for Effective Earthing Solutions

Our Earth Wire Tension Clamp Compression Type is meticulously manufactured, incorporating specifications based on detailed drawings. Each clamp undergoes rigorous surface treatment with hot dip galvanization, ensuring corrosion resistance and enduring performance in industrial environments. The use of mild steel and adherence to IS Standards elevate its reliability and structural integrity.

Optimized for Industrial Applications Across India

With design parameters tailored as per drawing, this tension clamp caters to industrial installation and maintenance needs. The gun-type shape facilitates easy handling and secure earth wire attachment, while the standardized thickness and height guarantee compatibility with varied setups. The product is available for manufacturers, suppliers, traders, and retailers throughout the country.

FAQs of Earth Wire Tension Clamp Compression Type:

Q: How is the Earth Wire Tension Clamp Compression Type installed for industrial use?

A: The clamp is installed in accordance with detailed drawing specifications. Its gun-type shape and standardized dimensions simplify the attachment process, ensuring secure connection of earth wires in various industrial setups.Q: What materials and surface treatments are used for this tension clamp?

A: It is constructed from mild steel and finished with hot dip galvanization, following IS specifications. This treatment enhances resistance to rust and environmental wear, extending the lifespan of the clamp.Q: When should I consider replacing or inspecting the tension clamp?

A: You should inspect the clamp at regular maintenance intervals or if there is visible corrosion, mechanical damage, or after its 12-month warranty period. Routine checks are important to ensure continuous safety and performance.Q: Where is this clamp primarily utilized within industrial operations?

A: This clamp is used in power distribution and earthing setups, commonly found in substations, transmission systems, and other industrial facilities across India to secure earth wires effectively.Q: What is the process behind ensuring the clamp meets quality standards?

A: Manufacturing follows IS specification guidelines, with each clamp undergoing hot dip galvanization and welding as per standard norms. Thorough quality checks ensure compliance with design and safety requirements.Q: How does the hot dip galvanized coating benefit the tension clamp?

A: Hot dip galvanization provides a durable, protective layer against corrosion, ensuring the clamp maintains its mechanical integrity and safety over prolonged periods in demanding industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earth Wire Hardware Fittings Category

Earthing Pipe

Price 750.00 - 1200.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : G.I. Pipe

Out Coating : Hot Dip Galvanized

Design : As per Drawing

Thickness : As per Drawing Millimeter (mm)

Earth Wire Tension Clamp Bolted Type

Price 350.00 - 370.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Malleable Cast Iron with Forged Anchor Shackle and Bolt, nut, washer

Out Coating : Hot Dip Galvanized

Design : As per Drawing

Thickness : As per Drawing Millimeter (mm)

Earth Wire P.g. Clamp

Price 120.00 - 150.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : M.S. Plate

Out Coating : Hot Dip Galvanized

Design : As per Drawing

Thickness : As per Drawing Millimeter (mm)

Midspan Compression Joint for Earth Wire

Price 150.00 - 200.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Material : SS and Aluminium Alloy

Out Coating : N.A.

Design : As per Drawing

Thickness : As per Drawing Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese