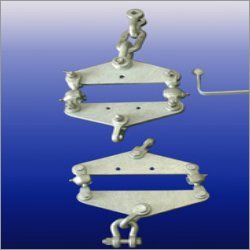

Double Tension Hardwares

Double Tension Hardwares Specification

- Product Type

- Double Tension Hardware

- Material

- Mild Steel / Alloy Steel

- Welding Standard

- IS Standards

- Capacity

- Upto 120KN

- Application

- Transmission Line, Pole Line Fittings

- Galvanization Standard

- IS 2629 / IS 4759

- Out Coating

- Hot Dip Galvanized

- Standard

- IS / IEC

- Shape

- Double Tension

- Surface Treatment

- Galvanized

- Height

- Custom Available

- Voltage

- 11KV - 400KV

- Design

- Robust, Precision Engineered

- Thickness

- 5 mm - 20 mm

- Color

- Silver

- Installation Type

- Easy to install, field assembly

- Finishing

- Uniform zinc coating

- Packing Type

- Wooden Box / Carton

- Corrosion Resistance

- Excellent due to hot dip galvanization

- Tensile Strength

- High, suitable for heavy electrical loads

- Usage

- Outdoor electrical transmission

- Weight

- As per drawing or order

- Temperature Range

- -10°C to 55°C

Double Tension Hardwares Trade Information

- Minimum Order Quantity

- 1000 Pieces

- Supply Ability

- 3000 Pieces Per Month

- Delivery Time

- 5 Days

- Sample Available

- Yes

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Packaging Details

- Wooden Crate, Corrugated Box & Customization.

- Main Domestic Market

- All India

About Double Tension Hardwares

Our organization is a prominent manufacturer and supplier of Double Tension Hardware that is used in various electrical applications to bear voltage fluctuations. The offered hardware is manufactured by making use of the finest grade raw material with the help of latest techniques under the supervision of our experienced professionals. The offered hardware is tested by our quality experts on various quality parameters to confirm durability prior to dispatch it from our end. Our offered Double Tension Hardware is made available in various specifications at reasonable prices.

Features:

- Dimensional accuracy

- High durability

- Optimum strength

- Robustness

Exceptional Corrosion Protection

With a hot dip galvanized finish in accordance to IS 2629 / IS 4759 standards, Double Tension Hardwares provide excellent resistance to corrosion, ensuring durability and reliability in outdoor environments exposed to variable weather conditions.

Effortless Installation and Field Assembly

Designed for practicality and convenience, these hardware systems feature an easy-to-install mechanism and field-assembly capabilities, reducing installation time and labor costs. Custom heights and weights based on order facilitate versatile project integration.

High Strength for Heavy Electrical Loads

Engineered from mild and alloy steel, Double Tension Hardwares offer high tensile strength and are suitable for transmission lines handling up to 120KN. Their robust design guarantees secure operation under demanding electrical loads and voltages ranging from 11KV to 400KV.

FAQs of Double Tension Hardwares:

Q: How is corrosion resistance achieved in Double Tension Hardwares?

A: Corrosion resistance is ensured by hot dip galvanization, which provides a uniform zinc coating complying with IS 2629 and IS 4759 standards, making these hardwares highly suitable for prolonged outdoor use.Q: What is the installation process for these hardware systems?

A: Double Tension Hardwares are designed for easy installation and field assembly, allowing for quick and efficient setup by following standard industry practices at the transmission or pole line sites.Q: When are Double Tension Hardwares typically used in electrical systems?

A: These hardware solutions are used during the construction and maintenance of outdoor electrical transmission and pole lines, especially where high strength and corrosion resistance are necessary.Q: Where can Double Tension Hardwares be applied?

A: Double Tension Hardwares are ideal for outdoor environments across India, particularly in electrical transmission and pole line installations exposed to varying temperatures and weather conditions.Q: What advantages does hot dip galvanization offer for these fittings?

A: Hot dip galvanization significantly increases the lifespan and durability of the hardware by providing comprehensive protection against rust and corrosion, reducing maintenance requirements.Q: How do Double Tension Hardwares accommodate specific project requirements?

A: By offering custom heights, weights according to order or drawing, and precision engineering, these products can be tailored to meet unique transmission line or pole fitting needs.Q: What benefits come with using Double Tension Hardwares from a certified manufacturer or supplier?

A: Sourcing from certified manufacturers and suppliers assures strict compliance with IS and IEC standards, robust performance, and consistent quality for critical electrical transmission applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Tower Line Hardware Fittings Category

Socket Clevis

Minimum Order Quantity : 1000 Pieces

Color : Silver

Application : Overhead Transmission Line, Pole Line Hardware

Product Type : Socket Clevis

Voltage : Up to 120 kV (For Transmission Line Use)

Double Tension Fittings

Price Range 200.00 - 250.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Silver

Application : HT/LT Transmission Line

Product Type : Double Tension Fitting

Voltage : Up to 220 kV

Clevis Eye

Price Range 50.00 - 100.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Silver

Application : Transmission Line Hardware

Product Type : Clevis Eye

Voltage : Upto 33 kV

Vibration Damper

Price Range 350.00 - 600.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Color : Silver

Application : Overhead Power Line

Product Type : Vibration Damper

Voltage : Suitable up to 400 kV

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese