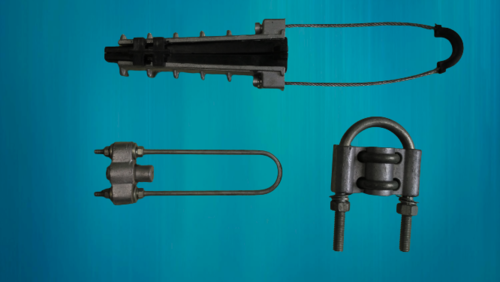

Anchoring and Dead End Clamps

Price 38.00 - 100.00 INR/ Piece

Anchoring and Dead End Clamps Specification

- Product Type

- Pole Line Equipments

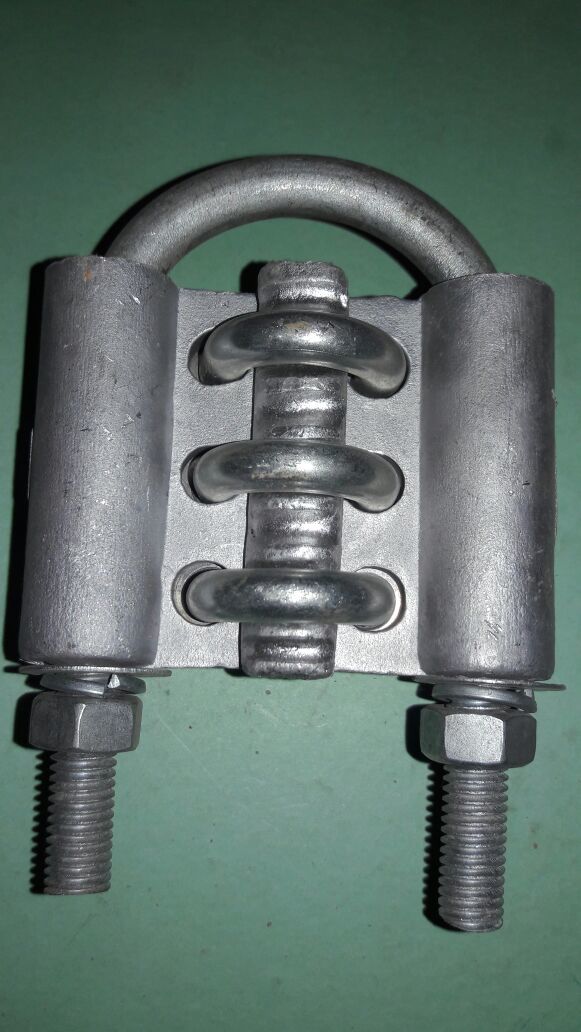

- Material

- Aluminium with mild Steel bolts & nuts.

- Welding Standard

- N.A.

- Application

- Pole Line Fittings

- Galvanization Standard

- REC Standard

- Out Coating

- N.A.

- Standard

- REC Specifications

- Shape

- In various shapes and sizes

- Surface Treatment

- Polished

- Height

- As per drawing Millimeter (mm)

- Design

- As per Drawing

- Thickness

- As per Drawing Millimeter (mm)

- Color

- Silver

- Warranty

- 12 Months

Anchoring and Dead End Clamps Trade Information

- Minimum Order Quantity

- 500 Pieces

- FOB Port

- Howrah

- Payment Terms

- Telegraphic Transfer (T/T), Cash Advance (CA), Cheque

- Supply Ability

- 5000 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Available

- No

- Packaging Details

- Gunny Bags

- Main Domestic Market

- All India

- Certifications

- Routine Test Report available

About Anchoring and Dead End Clamps

Product Description

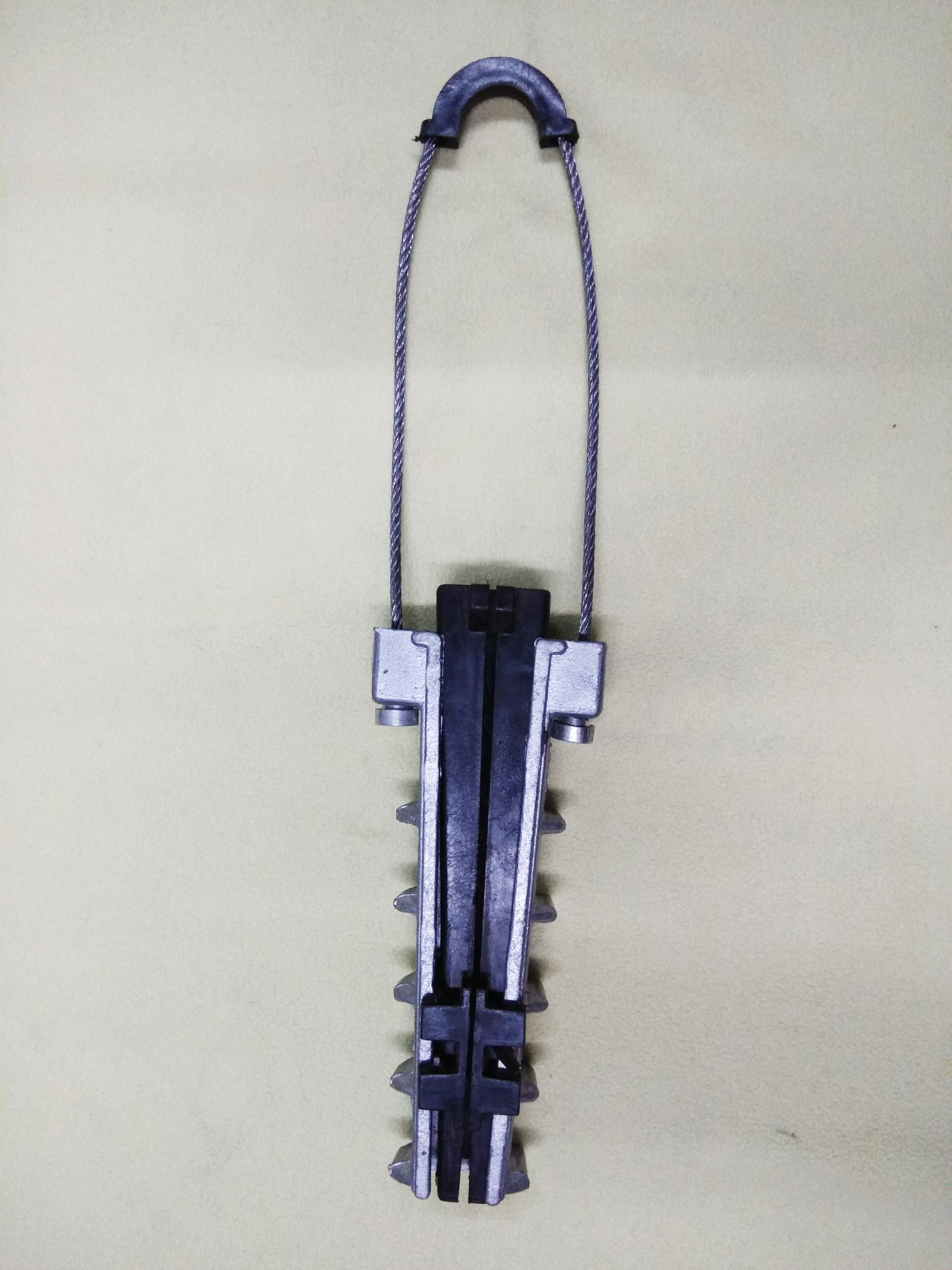

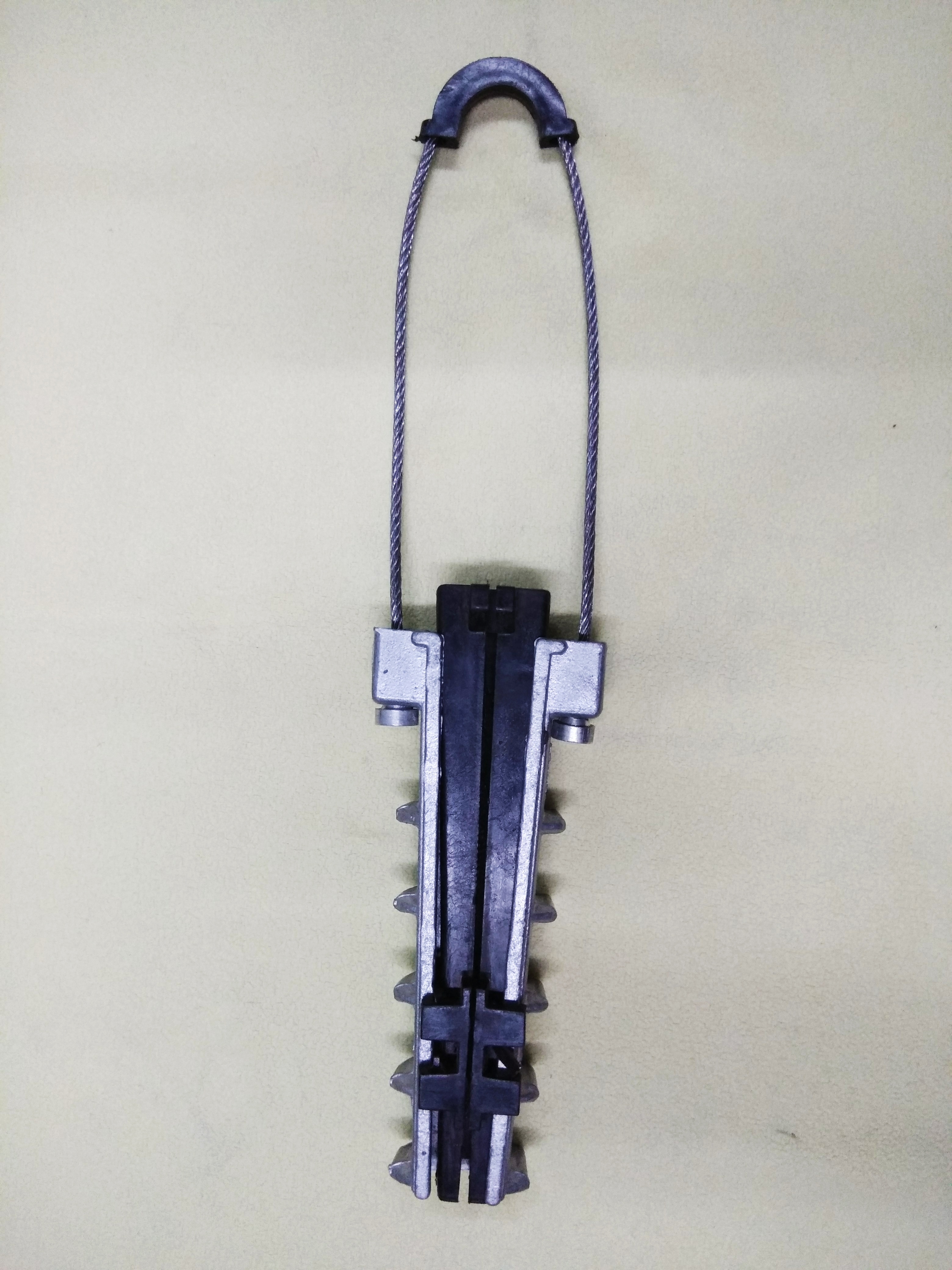

Being a reputed Supplier, we are providing a wide range of LT AB Cable Dead End Clamps or Anchor Clamps. The provided accessories are used in electrical and construction sectors. Our offered accessories are manufactured with utmost precision with the latest technology at our certified Vendors end. Our entire product range ensures easy installation and is abrasion resistant. They are delivered in standard lengths and thickness and can be customized as per the requirement.

Features

- Excellent flexibility

- High durability

- Non-inflammable

- Corrosion proof

Tailored Design for Versatile Applications

Each anchoring and dead end clamp is designed to the customers drawing and specifications, ensuring compatibility with a wide range of pole line installations. The flexibility in shape and size supports diverse construction and maintenance needs within power distribution networks.

Quality Surface Protection for Enhanced Durability

The clamps undergo a meticulous polishing and galvanization process that meets REC standards. This surface treatment ensures resistance to corrosion, making them suitable for harsh weather and extending the products operational life.

FAQs of Anchoring and Dead End Clamps:

Q: How are anchoring and dead end clamps installed for pole line fittings?

A: Installation involves attaching the clamp to a designated pole line fitting using mild steel bolts and nuts. The process follows the design and thickness outlined in the drawing, ensuring a secure fit and stable electrical termination.Q: What surface treatments are applied to these clamps and why are they important?

A: The clamps receive polishing and galvanization as per REC Standard, enhancing their resistance to corrosion and environmental wear. This treatment improves longevity and maintains electrical safety standards.Q: When should REC Standard anchoring and dead end clamps be used?

A: These clamps should be used whenever secure anchoring or safe termination of electrical lines is required in pole line installations, especially where compliance with REC Specifications is mandatory.Q: Where are these clamps typically utilized?

A: They are predominantly used in power transmission and distribution projects across India, particularly for overhead pole line fittings in urban, suburban, and rural environments.Q: What is the manufacturing process for clamps with this specification?

A: Clamps are manufactured using high-grade aluminium and mild steel for the bolts and nuts. The process respects precise dimensions from customer drawings, followed by surface treatmentincluding polishing and galvanizationto comply with REC standards.Q: How do the design and material choice benefit the end-user?

A: The use of aluminium ensures lightweight strength, while mild steel bolts and nuts provide secure fastening. Adherence to design specifications guarantees compatibility, and finished surface treatments prolong service life even under challenging conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aerial Bunch Cable Accessories Category

Insulated Piercing Connectors

Price 35.00 - 75.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Out Coating : N.A.

Application : Pole Line Fittings

Standard : Standard Specifications

Tension and Suspension Aluminium Pole Brackets

Price 90.00-110.00 INR / Piece

Price Range 20.00 - 55.00 INR / Piece

Minimum Order Quantity : 1000 Pieces

Out Coating : N.A.

Application : Pole Line Fittings

Standard : REC Specifications

LT NFC SUSPENSION CLAMPS

Price 50.00 - 80.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Out Coating : N.A.

Application : Pole Line Fittings

Standard : REC Specifications

Suspension Clamp for AB Cables

Price 40.00 - 125.00 INR / Piece

Minimum Order Quantity : 500 Pieces

Out Coating : N.A.

Application : Pole Line Fittings

Standard : REC Specifications

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese