11 Kv Polymer Drop Out Fuse

Price 4500.00-5500.00 INR/ Set

11 Kv Polymer Drop Out Fuse Specification

- Product Type

- Pole Line Equipments

- Material

- Polymer

- Welding Standard

- As per Standard

- Application

- Pole Line Fittings and Substation Fittings

- Galvanization Standard

- Standard

- Out Coating

- Galvanized Channel

- Standard

- IS Specifications

- Shape

- Rectangular

- Surface Treatment

- Hot Dip Galvanized

- Design

- As per Drawing

- Thickness

- As per Drawing Millimeter (mm)

- Color

- Silver with Grey Polymer Insulators and Yellow FRP Fuse Barrel.

- Warranty

- 12 Months

11 Kv Polymer Drop Out Fuse Trade Information

- Minimum Order Quantity

- 1 Set

- FOB Port

- Howrah

- Payment Terms

- Cheque, Telegraphic Transfer (T/T), Cash Advance (CA)

- Supply Ability

- 100 Sets Per Month

- Delivery Time

- 30 Days

- Packaging Details

- Wooden Box.

- Main Domestic Market

- All India

- Certifications

- Routine Test Reports available.

About 11 Kv Polymer Drop Out Fuse

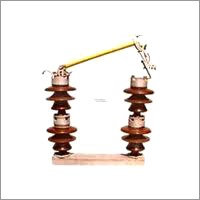

11 Kv Polymer Drop Out Fuse

11 KV Polymer Drop Out Fuse are used for 11 KV Distribution Lines and Substations. The function is to restrict the overload on the charged line and save the Electrical Equipments for any damage.

Engineered for Reliability

Our 11 Kv Polymer Drop Out Fuse combines high-grade polymer material with galvanized structural components to deliver durable performance in demanding environments. The products rectangular shape and custom design ensure seamless integration into pole line and substation applications, guaranteeing secure and stable electrical connections.

Standards and Customization

Each fuse is meticulously produced in compliance with IS specifications and can be customized as per drawing requirements. The combination of silver-grey polymer insulators and a yellow FRP barrel not only serves functional purposes but also provides visual clarity for operators during maintenance checkpoints.

FAQs of 11 Kv Polymer Drop Out Fuse:

Q: How is the 11 Kv Polymer Drop Out Fuse installed on pole lines or substations?

A: The fuse is typically mounted using galvanized hardware in pole line or substation settings. Its design, as per the provided drawing, allows for precise installation and easy integration with existing fittings.Q: What standards and materials are used in the construction of this fuse?

A: This fuse is crafted from high-quality polymer materials with a galvanized channel and silver-grey polymer insulators. It is produced following IS specifications, ensuring standard compliance and safety.Q: When should the 11 Kv Polymer Drop Out Fuse be replaced?

A: Replacement is recommended if there are visible signs of damage, malfunction, or after a maximum service period as specified in the maintenance guidelines or warranty term of 12 months, whichever comes first.Q: Where can I use this fuse in electrical installations?

A: It is ideally suited for use in pole line and substation fittings across medium voltage networks, making it applicable for a wide range of distribution infrastructure in India.Q: What is the process used to ensure surface durability?

A: The surface components undergo hot dip galvanization, providing exceptional corrosion resistance and enhancing durability for long-term outdoor operation.Q: How does the design as per drawing benefit the customer?

A: Customization according to specific drawings ensures optimal fit and function for various installation scenarios, minimizing downtime and simplifying the integration process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drop Out Fuse Category

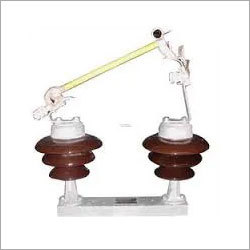

11kv Dropout Fuse

Minimum Order Quantity : 1 Set

Surface Treatment : Hot Dip Galvanized

Product Type : Electrical Overhead Line

Material : Porcelain Insulator, Brass Contacts, Iron parts & Fibre Tube

Color : Silver with Brown glazed Porcelain Insulators

22 KV Porcelain Dropout Fuse

Price 13000.00 - 14000.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Treatment : Hot Dip Galvanized

Product Type : Pole Line Equipments

Material : Porcelain Insulators, Brass Contacts and G.I. Iron Channel

Color : Silver with Brown glazed Porcelain Insulators

33 Kv Drop Out Fuse

Price 10000.00 - 14500.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Treatment : Hot Dip Galvanized

Product Type : Drop Out Fuse

Material : Porcelain Insulator, Brass Contacts, Iron parts & Fibre Tube

Color : Silver with Brown glazed Porcelain Insulators

11 Kv Drop Out Fuse

Price 4500.00-6000.00 INR / Set

Minimum Order Quantity : 1 Set

Surface Treatment : Hot Dip Galvanized

Product Type : Pole Line Equipments

Material : Porcelain type

Color : Silver with Brown glazed Porcelain Insulators

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese