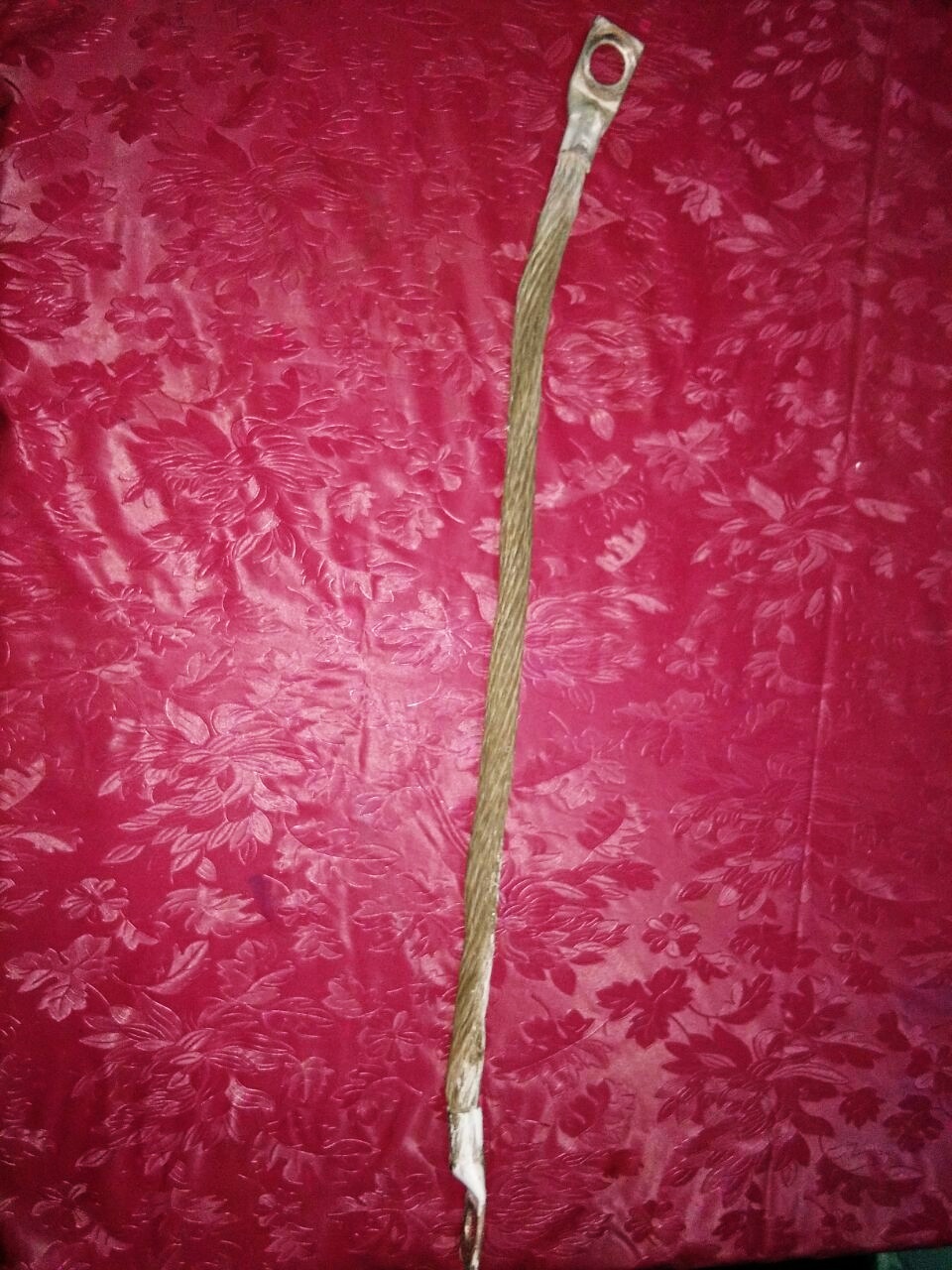

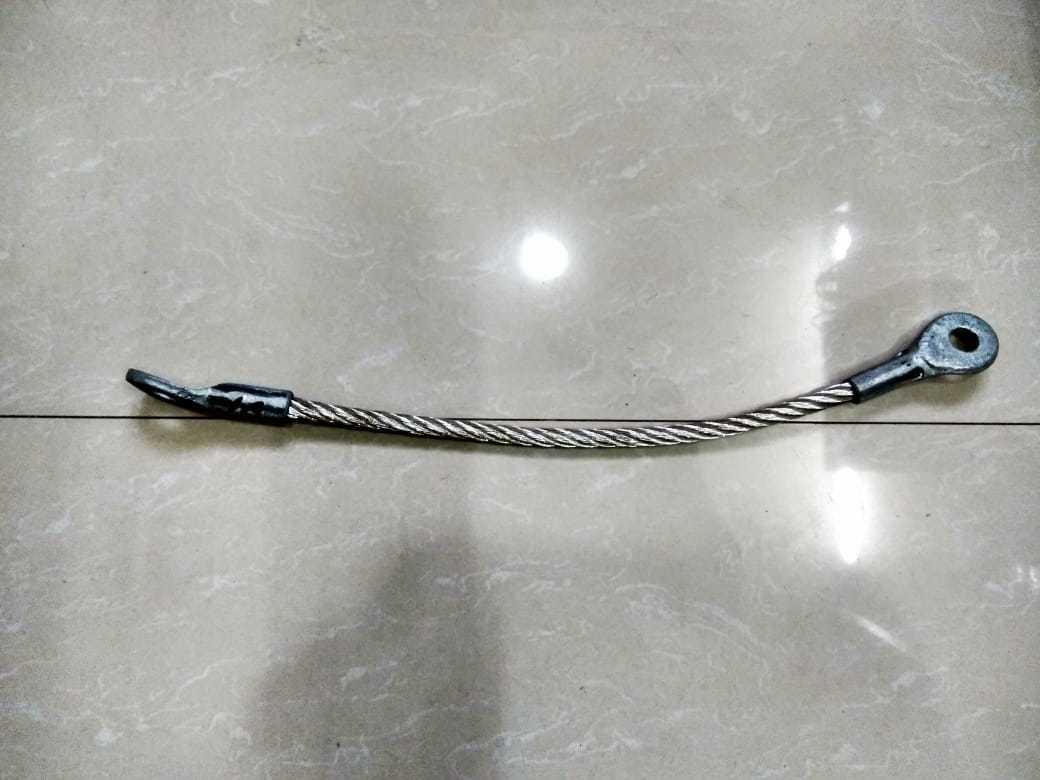

Copper Earth Bond

Price 400.00 - 450.00 INR/ Piece

Copper Earth Bond Specification

- Product Type

- Earth Wire Hardware Fittings

- Material

- Copper with HDG or Tinned Copper Lugs

- Welding Standard

- N.A.

- Application

- Pole Line Fittings, Substation Fittings & Tower Fittings

- Galvanization Standard

- IS SPECIFICATION

- Out Coating

- Tinned

- Standard

- IS Specifications

- Shape

- Rectangular

- Surface Treatment

- Polished

- Height

- N.A. Millimeter (mm)

- Design

- As per Drawing

- Thickness

- As per Drawing Millimeter (mm)

- Color

- Silver

- Warranty

- 12 Months

Copper Earth Bond Trade Information

- Minimum Order Quantity

- 10 Pieces

- FOB Port

- Howrah

- Payment Terms

- Cheque, Cash Advance (CA), Telegraphic Transfer (T/T)

- Supply Ability

- 1000 Pieces Per Month

- Delivery Time

- 30-45 Days

- Packaging Details

- Gunny Bags

- Main Domestic Market

- All India

- Certifications

- Routine Test Report available

About Copper Earth Bond

Copper Earth Bond

Flexible Copper Bond serves as the earthing bond for which provisions are made in the Earth wire Suspension & Tension Clamps for attaching with the tower. Copper bonds are usually made of stranded tinned copper wire duly crimped by tinned copper lugs at both ends. It is also available in Mild steel duly HDG as per Customers requirement.

Custom Engineering for Versatile Applications

Each Copper Earth Bond is tailored according to specific project requirements, ensuring a precise fit for diverse applications such as pole line fittings, substations, and towers. An adherence to client drawings ensures compatibility and reliable performance across various electrical infrastructures.

IS Specification Compliance Ensures Reliability

All Copper Earth Bonds are produced in line with stringent IS specifications for both galvanization and overall quality. This compliance guarantees consistency, safety, and optimal conductivity, making the product suitable for critical installations.

Durable, Corrosion-Resistant Finish

The combination of tinned or hot-dip galvanized copper and a polished surface treatment provides robust resistance to corrosion. The silver coating not only enhances conductivity but also extends the bonds operational lifespan, even in harsh outdoor environments.

FAQs of Copper Earth Bond:

Q: How is the Copper Earth Bond typically installed in electrical infrastructure?

A: The Copper Earth Bond is mounted as per the design and sizing indicated in client drawings, which ensures adaptability for pole line, substation, or tower fittings. Installation is straightforward since welding standards are not applicable, and it is compatible with HDG or tinned copper lugs for secure connections.Q: What standards does the Copper Earth Bond conform to?

A: This product meets all relevant IS specifications regarding material thickness and galvanization standards. Both the copper used and the external coating are in accordance with set IS requirements, ensuring electrical safety and long-term reliability.Q: When should I use a tinned Copper Earth Bond over a standard HDG option?

A: Tinned Copper Earth Bonds are ideal when additional corrosion resistance is desired, especially in environments with high humidity or chemical exposure. The tinned finish enhances durability, making it well-suited for demanding applications or areas prone to corrosion.Q: Where can I source Copper Earth Bonds in India?

A: These Copper Earth Bonds are available nationwide in India through a network of manufacturers, retailers, suppliers, and traders. You can procure them directly from specialized electrical infrastructure suppliers who offer customization as per your project drawings.Q: What is the process for customizing the shape and design of the Copper Earth Bond?

A: Customization is based on engineering drawings provided by the client. Manufacturers fabricate the earth bond to precise dimensions and design specifications, ensuring a perfect match for your specific application, whether for pole lines, substations, or towers.Q: What are the advantages of the polished, tinned coating on the Copper Earth Bond?

A: The polished, tinned coating significantly enhances the products resistance to corrosion while maintaining superior electrical conductivity. This results in improved performance and an extended operational lifespan, particularly in outdoor and industrial environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Earth Wire Hardware Fittings Category

Midspan Compression Joint for Earth Wire

Price 150.00 - 200.00 INR / Piece

Minimum Order Quantity : 20 Pieces

Material : SS and Aluminium Alloy

Application : Electrical & Construction Sectors

Height : As per drawing Millimeter (mm)

Out Coating : N.A.

Vibration Dampers

Minimum Order Quantity : 10 Pieces

Material : Mild Steel

Application : Substations & Industrial

Height : As per drawing Millimeter (mm)

Out Coating : Hot Dip Galvanized

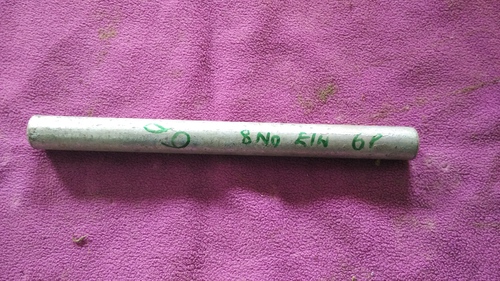

Repair Sleeves For Earth Wire

Price 90.00 - 100.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : Aluminium and Mild Steel

Application : Electrical & Construction Sectors

Height : As per drawing Millimeter (mm)

Out Coating : N.A.

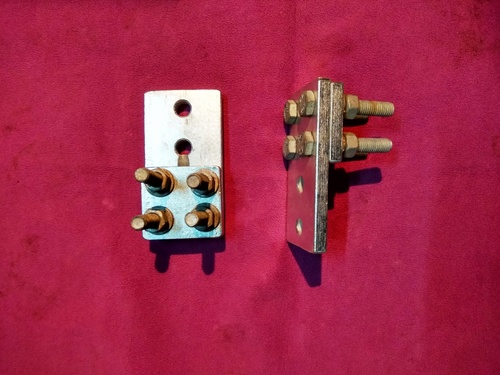

Pad Clamps For Earth Wire

Price 340.00 - 360.00 INR / Piece

Minimum Order Quantity : 10 Pieces

Material : M.S. Plate

Application : Electrical & Construction Sectors

Height : As per drawing Millimeter (mm)

Out Coating : Hot Dip Galvanized

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese